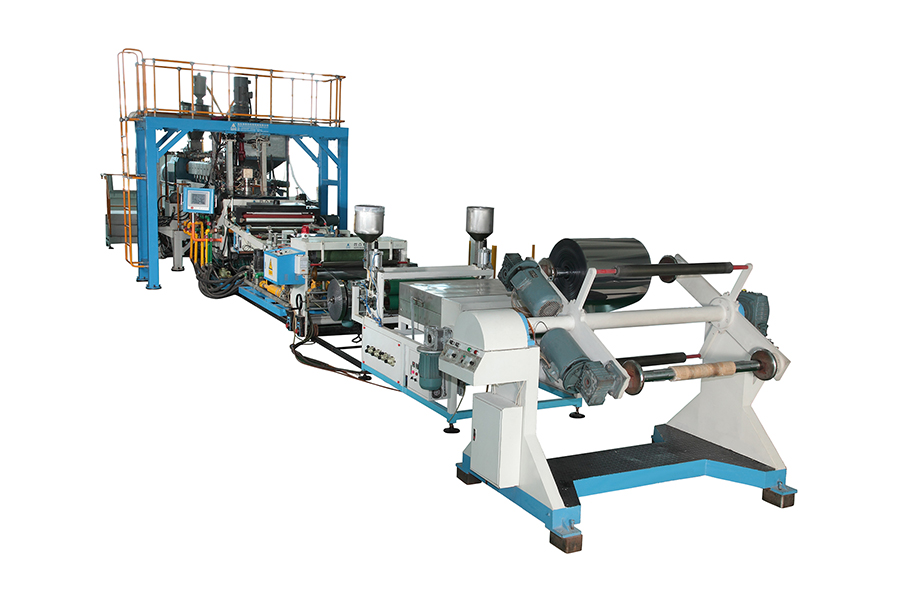

I-Twin Screw Plastic Extruder (i-PET Sheet Extrusion)

IParameter yobuGcisa

I-WJP(PET)75B-1000 I-Twin Screw Plastic Extruder (i-PET Sheet Extrusion)

| Izinto ezisebenzayo | Ukuchazwa kwesikruru | Ubukhulu bephepha | Ububanzi bephepha | Umthamo wokwandiswa | Umthamo ofakiweyo |

| mm | mm | mm | kg/h | kW | |

| APET, PLA | Φ75 | 0.18-1.5 | ≤850 | 300-400 | 280 |

Iimbonakalo

I-1.I-screw element ithatha uhlobo lwe-conjugate umsonto ophindwe kabini ngoyilo lokuphucula ikhompyutha kunye nomatshini ochanekileyo. Ngaphandle koko, i-screw yenzelwe kunye ne-multivariate yokudibanisa ukwakhiwa kwemodyuli, enokucoca okuphezulu kunye nokutshintshana.

2. Ngokusekelwe kwiminyaka yoyilo lwamava e-screw configuration, i-AUTO inokwenza ulungelelwaniso olufanelekileyo lwezinto ezisijiva ezidityanisiweyo ngoncedo lweteknoloji yesoftware. Ke ngoko, inokuqonda ukuhanjiswa kwezinto zeplastikhi, ukucocwa okuxutyiweyo, ukucheba kunye nokusasazwa, i-homogenization, i-volatilization kunye ne-devolatilization, gcina uxinzelelo kunye ne-extrusion kunye neminye imisebenzi ngokwemathiriyeli yabathengi kunye netekhnoloji yokucubungula.

3. Umbhobho womatshini wenzelwe i-vacuum exhausting ikhonkco ezimbini eziqinisekisa ukukhupha ngokupheleleyo umphunga wamanzi kunye nezinye iigesi eziguqukayo.

4. I-twin screw plastic extruder yenzelwe i-melt dosing pump iqinisekisa imveliso yobungakanani kunye noxinzelelo oluzinzileyo, olunokunceda ekuqondeni ulawulo oluzenzekelayo oluvaliweyo loxinzelelo kunye nesantya.

5. Umatshini opheleleyo uthatha inkqubo yokulawula i-PLC, enokuqonda ukulawula ngokuzenzekelayo kwi-parameter setting, ukusebenza komhla, impendulo, ukwesaba kunye neminye imisebenzi.

Inzuzo

Enye yezona zinto zibalulekileyo kwi-twin screw extruders zeplastiki zizinto zazo. Ukhathalelo olukhulu luthathiwe ukuqinisekisa ukusebenza kakuhle kunye nokuqina ngokuqesha isikrufu se-twin-flight conjugated. Olu lwakhiwo lukhethekileyo ludityaniswe neteknoloji yokuphucula ikhompyuter kunye nomatshini ochanekileyo, okukhokelela ekusebenzeni okuphezulu. Izinto ezisijiva zikwabonisa ulwakhiwo lwemodyuli oluphezulu lokuzicoca kunye nokutshintshiselana. Oku kuqinisekisa inkqubo yokuvelisa egudileyo kwaye engaphazanyiswa, ukunciphisa ixesha lokunciphisa kunye nokwandisa imveliso.

Iminyaka yamava kwi-screw configuration design ivumela ukuba siqhubele phambili ukusebenza kwe-extruder. Ngoncedo lwetekhnoloji yesoftware ye-cutting-edge, singakwazi ukuqwalasela ngokugqibeleleyo imidibaniso yesikrufu. Oku kuthetha ukuba i-extruders yethu inokudlulisa ngokufanelekileyo kwaye ifake iplastiki, iqinisekisa imveliso esemgangathweni ephezulu. Itekhnoloji yethu yesoftware idlala indima ebalulekileyo ekufezekiseni iimeko ezifanelekileyo zokusebenza, ukuqinisekisa ukuba abathengi bethu bayakwazi ukuvelisa owona mgangatho uphezulu wephepha lePET.

Enye inzuzo ebalulekileyo ye-twin screw extruders zeplastiki kukuguquguquka kwazo. Nokuba uvelisa iphepha le-PET lokupakisha, i-thermoforming okanye nasiphi na esinye isicelo, ii-extruders zethu zinokuhlangabezana neemfuno zakho ezizodwa. Iyakwazi ukucubungula iindidi ezininzi zemathiriyeli, ibonelela ngokuguquguquka okukhulu kwinkqubo yakho yokuvelisa. Ukongeza, ii-extruders zethu zenzelwe uhlengahlengiso olulula nolukhawulezayo, kukuvumela ukuba utshintshe ngokulula phakathi kweefomathi ezahlukeneyo zemveliso. Oku kuguquguquka konga ixesha kunye nemali, kwenza ii-extruders zethu zibe sisisombululo esinexabiso elisebenzayo kwiimfuno zakho ze-PET sheet extrusion.